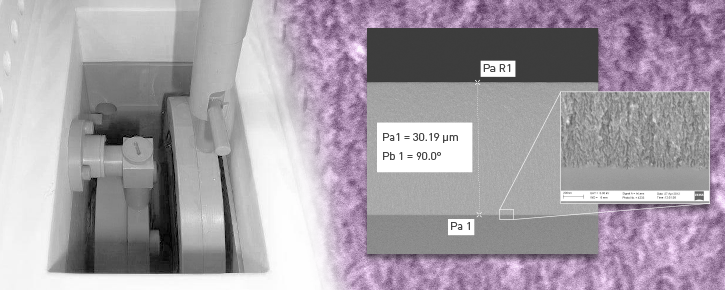

Complete wet etching system for porous silicon formation

Porous silicon (PS) has gained wide-spread attention over the last decade for its interesting material properties, including nanometer features and extremely high specific surface area. Applications are, amongst others, humidity sensors, particle filters, optical elements and biochemical matrices. Microporous silicon is fabricated by etching silicon in HF-based solutions under applied voltage. Most fabrication processes for macroporous silicon need illumination in addition, an issue also addressed by AMMTs tools for PS formation.

AMMT’s line of PS equipment consists of:

Together, these products form a turn-key system for porous silicon etching, which is used by major players in the MEMS field.

For details please see the product pages.