Sticking free and dry silicon oxide removal

R&D setup for sticking free and dry silicon oxide removal

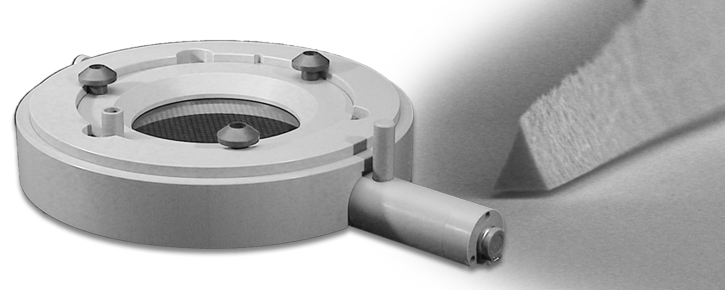

The HF vapor etcher consists of a reaction cell and heated wafer holder, in addition to an electronic control unit. HF vapor is generated passively from a small liquid reservoir at the bottom of the reaction cell. Only a minimal amount of about 60 - 80 ml of liquid HF is required. The HF Vapor Etcher Basic is perfectly adapted for R&D work in surface micromachining, SOI-MEMS, for dicing-free release, structure thinning, and many other applications.

Safety is an important issue when working with HF. AMMT's engineers have designed this easy-to-use and straight forward etching system with a maximum of security including special handling tools and a safety receptacle around the etcher in case of spillage. All parts in touch with liquid HF can be easily removed and cleaned.

AMMT's control unit delivered with the system allows for precise heating (typ. ± 0.2 °C) and has an integrated timer to control the etching process.

For more information, please download our product info below.

For a complete list of our product information sheets please see our Documentation Download Section.