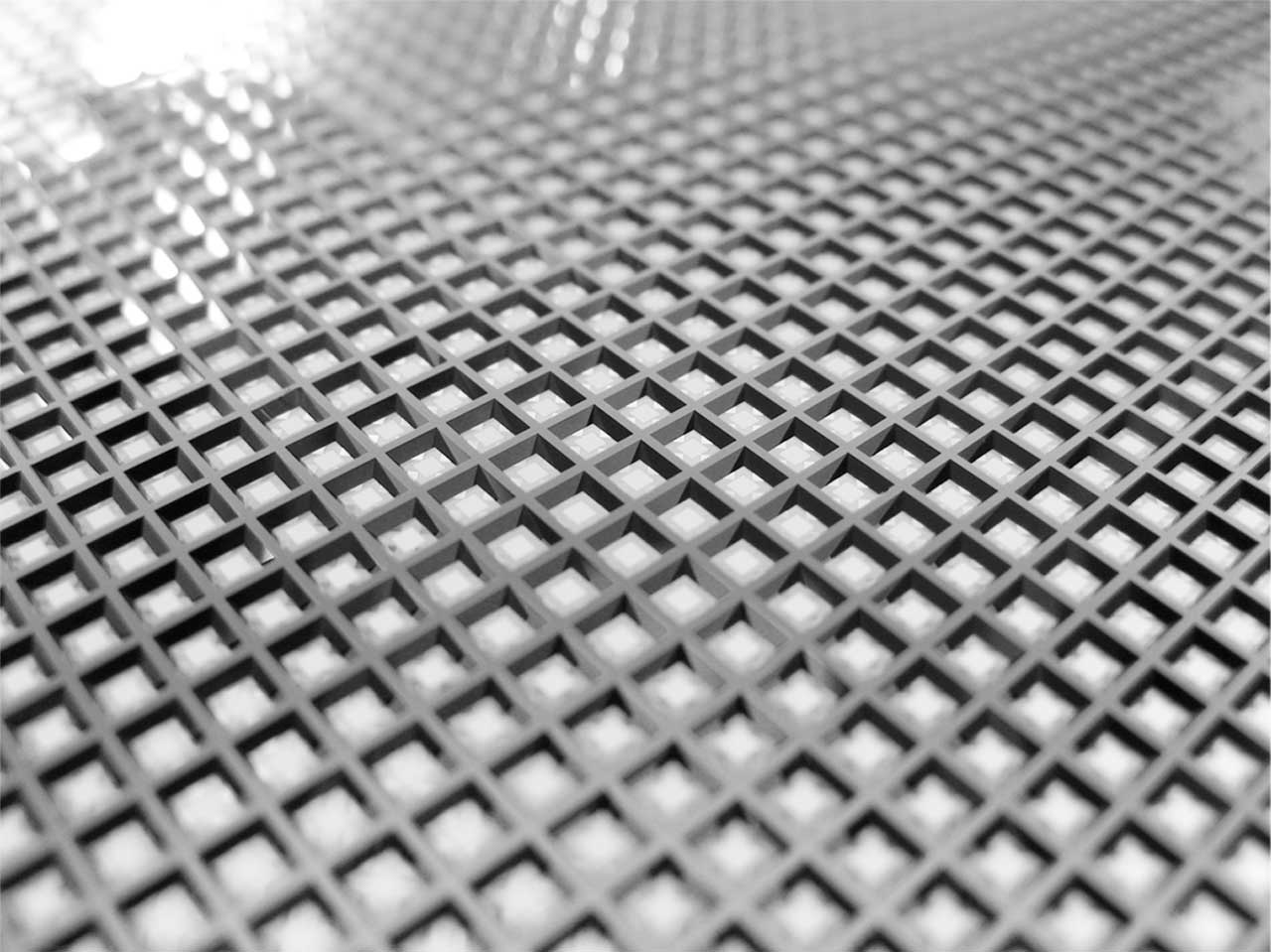

Complete wet etching system for porous silicon formation

Double cell HF tank for porous silicon etching with electrolye-backside contact

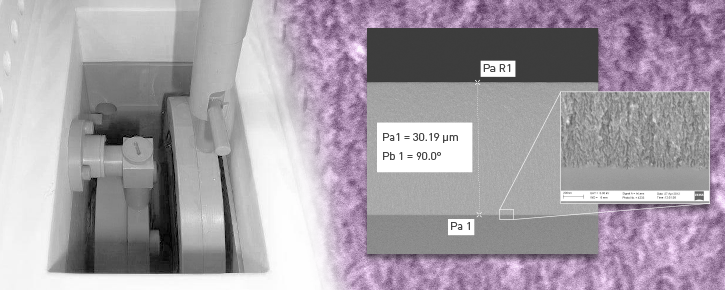

The MPSB wet etching system for porous silicon is a complete solution for porous silicon formation and electro-polishing of silicon. Together with our Porous Silicon Power Supply PS2, AMMT offers an all-in-one solution for this range of fabrication methods. The MPSB is available for 4", 6" and 8" wafer sizes. The MPSB double cell is available as a table-top setup or can be integrated into a dedicated wet-bench. For safety purposes, the system can be equipped with connections for continuous HF vapor extraction. PTFE drain valves are connected for direct HF disposal. As an option, an optical windows allows for light-assisted porous silicon formation. An HF resistant sapphire window, supported by thick quartz disks as protection against fracture, can be mounted into sealed flanges. If illumination is not necessary, blind covers can be mounted instead.

The wafer is mounted into a removable wafer holder, which is sealed with double O-rings. The wafer holder is then placed in front of the circular opening in the separation plate and is finally fixed in place by a pneumatic actor driven catch. Once the catch is closed, the cathode and anode cell are insulated from each other in the MOhm-range. Two platinum mesh electrodes, one in each cell, are used to contact the wafer from both sides. In order to ensure a homogeneous electrical field, the electrodes are of the same size as the wafer. After processing the wafer holder can be removed safely by means of a handling tool, the HF etchant remains in the tank. The first rinsing (and optionally fixation step) can be done with the wafer mounted into the wafer holder.

For more information, please download our product info below.

For a complete list of our product information sheets please see our Documentation Download Section.